MIL – micro & MACRO inspection loader

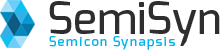

MIL8000 wafer autoloader and macro inspection station represents the most effective system to automatically load wafers on a microscope and to perform a wafer front and backside macro inspection.

It is a compact unit, which makes possible to load wafers on almost any microscope without the need of complex interfaces nor to change the microscope stage.

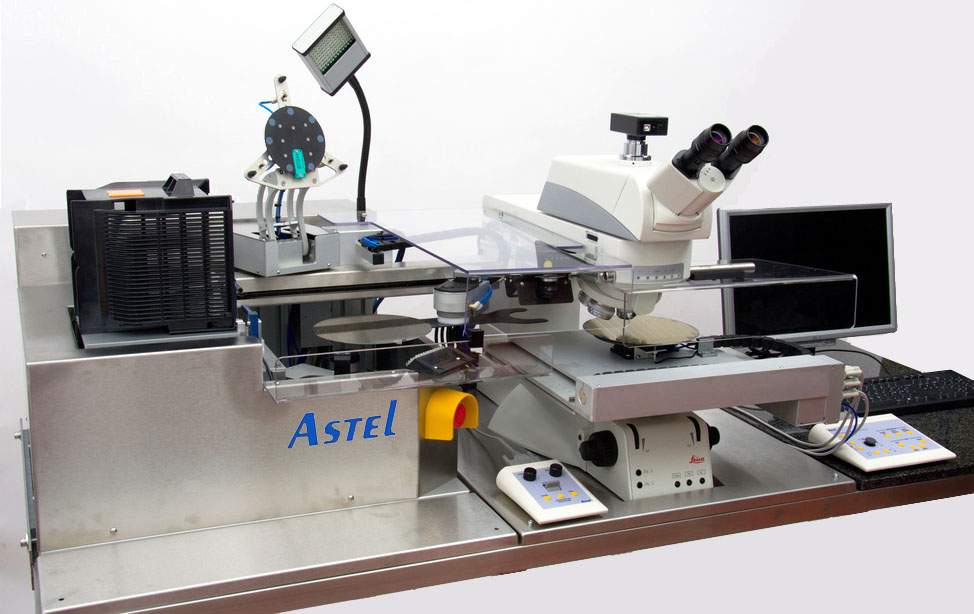

MACRO inspection is done by LED sources, with high efficiency and adjustable output level. The wafer backside inspection is done by a contactless Bernoulli unit which allows to inspect the whole surface in a single operation.

Bernoulli back inspection unit can handle even the most critical thin wafers in a safe and reliable mode.

This wafer inspection loader-unloader have been designed with some goals in mind: Safety, Affordability, Flexibility, Easy to use.

In one word: a S.A.F.E. Wafer Handling

“S” as SAFE

MIL has several features to ensure the safest wafer handling to avoid any possible damage to your precious devices.

Our autoloader is fully CE and SEMI compliant.

Wafer protrusion sensor and cross slot detection protect your devices from operator errors. A reliable wafer position measurement, with the evaluation of the critical distance between two wafers, allows a safe handling of wafers even with high bow and warpage.

Carbon fiber end effectors of proprietary design allow to handle wafers in an even more safe way, helping to avoid any scratch or damage to the surfaces. Also, TAIKO type wafers down to 40 µm can be inspected thanks to this special end effector.

MIL wafer inspection station is now featured by our autorecipe tool, which makes possible to define a new cassette profile with a simple guided operation and without the need of complex setups.

Once done the recipe, the loader will be able to handle wafers of any thickness from 150μm to 1000 μm, by automatically adapting the pickup levels to the real wafer positions as measured by the laser mapping sensor.

“A” as AFFORDABLE

An extremely very low Total Cost of Ownership (TCO) is achieved by a high reliable design where all components are well sized to withstand heavy loads (even MEMS bonded wafers) without maintenance.

Macro inspection is performed easily and the backside is viewed in a single pass.

Installation and setup times are reduced to the minimum possible.

“F” as FLEXIBLE

To increase the productivity, it features different wafer selection methods to cover any inspection need. The immediate wafer access and selection makes the system extremely easy, fast to setup and friendly to use.

A reduced cycle time is achieved by a deep optimization of control software.

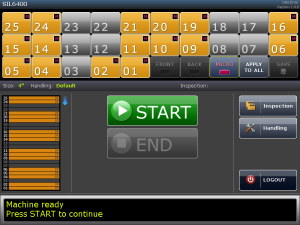

Different inspection types (Macro frontside, Macro backside or Micro) can be programmed for a whole carrier or even at wafer level.

MIL can be easily interfaced to different types of microscopes or 3D measurement instruments.

“E” as EASY

The system is featured by a powerful computer control with graphical touch screen and an user friendly interface.

Its software includes recipe management to easily switch between different handling configurations, like wafer thickness and bow or warpage.

Automatically detecting wafer size, it changes its configuration on the fly, without any hardware modification.

The operator need only one-click to start working.

Our autoloader has been designed for Leica DM8000 and it can be used with microscopes of several brands, like Nikon, Olympus, Zeiss, KLA-Vistec, INM100, INM200, DM4000 and DM6000 Leica and with 3D measurement systems.